Posts by Benjamin Henneberger

Separator Machines Working Principles: Lead Angle, Material Flow Path – How they affect your Productivity Throughput

What is the Lead Angle? The lead angle adjustment controls the path the material travels across the screen. In round vibratory separators, the lead angle can be best defined as the counterclockwise angle between the top and bottom weights when viewing the machine from above. When set to the correct lead angle, the material feed path…

Read MoreChoose the Right Deblinding Screen for your Application

Using a vibratory separator machine is a reliable method of sorting, classifying, and cleaning a wide range of materials, both dry and wet. Because the material is sorted through a wire mesh screen, some materials tend to clog the mesh openings, effectively limiting the capacity of the machine’s throughput. To avoid stopping the process to…

Read MoreHow to Keep Screen Replacement Cost Low

With the price of raw material skyrocketing, many manufacturers using Vibratory Separator Machines are wondering – how do we keep our costs of replacement screens at a manageable rate? According to the office of the U.S. Bureau of Labor Statistics, the stainless-steel index has increased more than 29.5% over the last year, realizing an approximate…

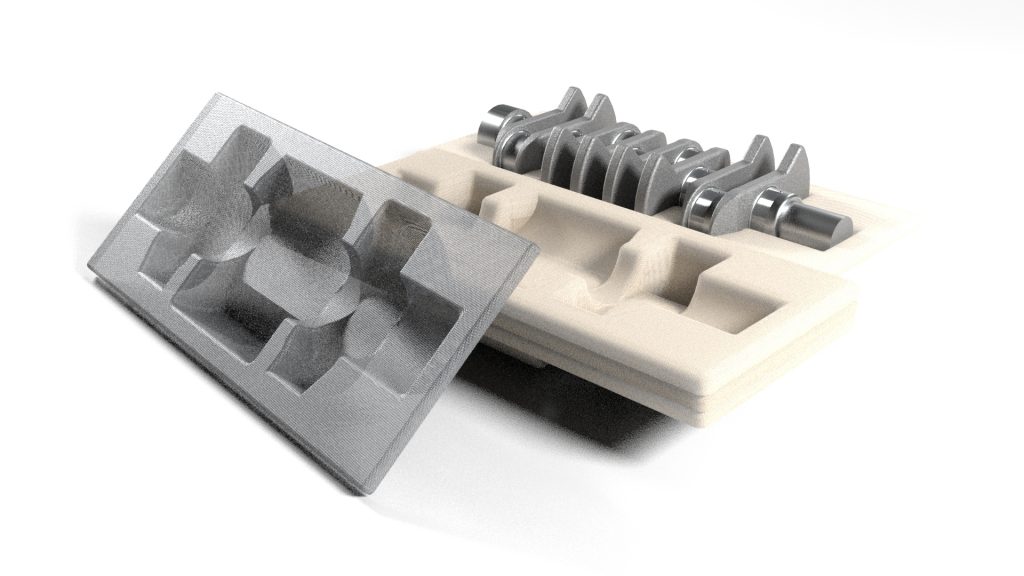

Read MoreCase Study: How one Fiber Molding Manufacturer significantly lowered their cost of production

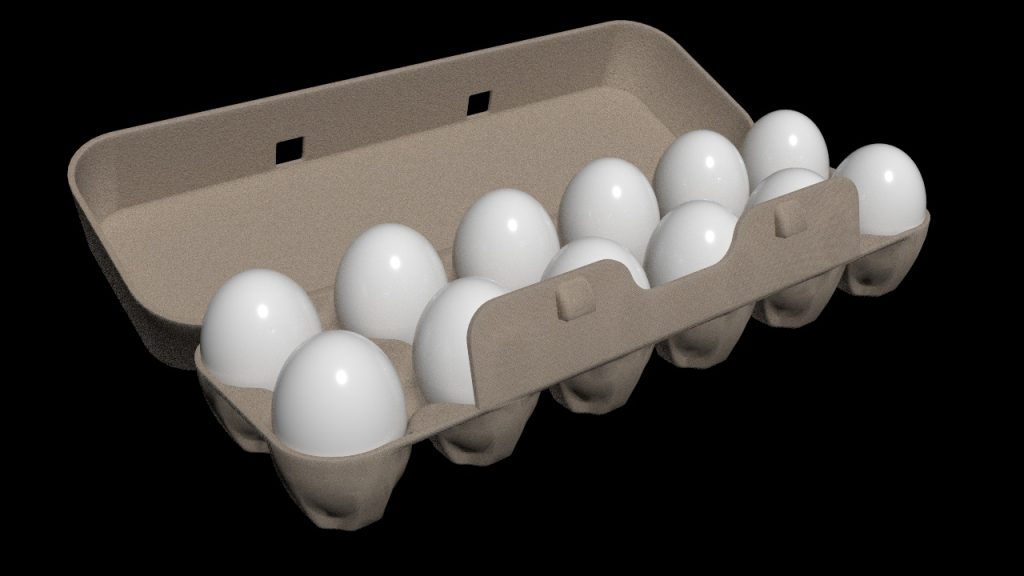

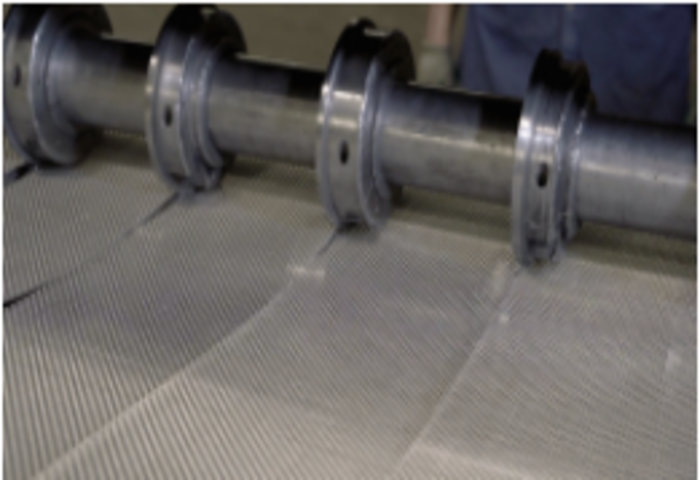

Production of Fiber molds (sometimes called Pulp molds) used for food and other containers has increased significantly in the last 10 years. Consumers are looking for more sustainable packaging, driving many companies to switch from plastic formed to fiber molded containers. According to the most recent report conducted by Fredonia Research for the International Fiber…

Read MoreFiber Molded Products: 6 Ways To Minimize Scrap

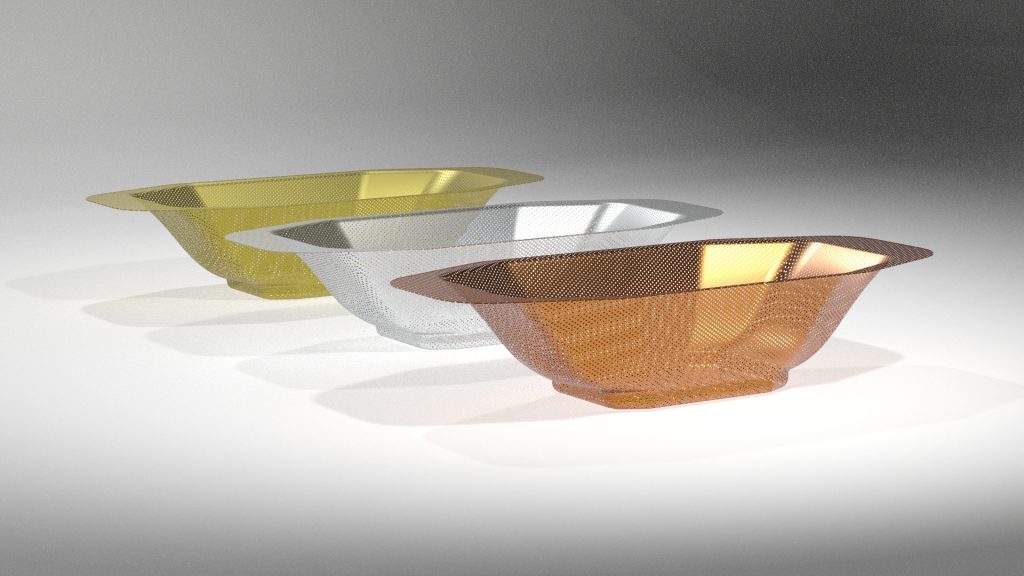

#1: Select Best Porous Media Type #2: Determine Correct Heat Treatment #3: Optimize Blank Layout Choosing the best porous media for your project is key to getting good quality, repeatable wire forms and the desired look and feel of the fiber mold. The media used will depend on size, finish, strength, and other factors required…

Read MoreFiber Molded Products: Minimizing Scrap and Lost Production Time when Drawing Wire Forms

In the metal fabrication industry, drawing has two meanings. One is the drawing of wire by taking it through a die to reduce its diameter. The second type of drawing is the process of forming metal, such as wire mesh or sheet metal, over a tool to create a three-dimensional shape. Through heat treating, the…

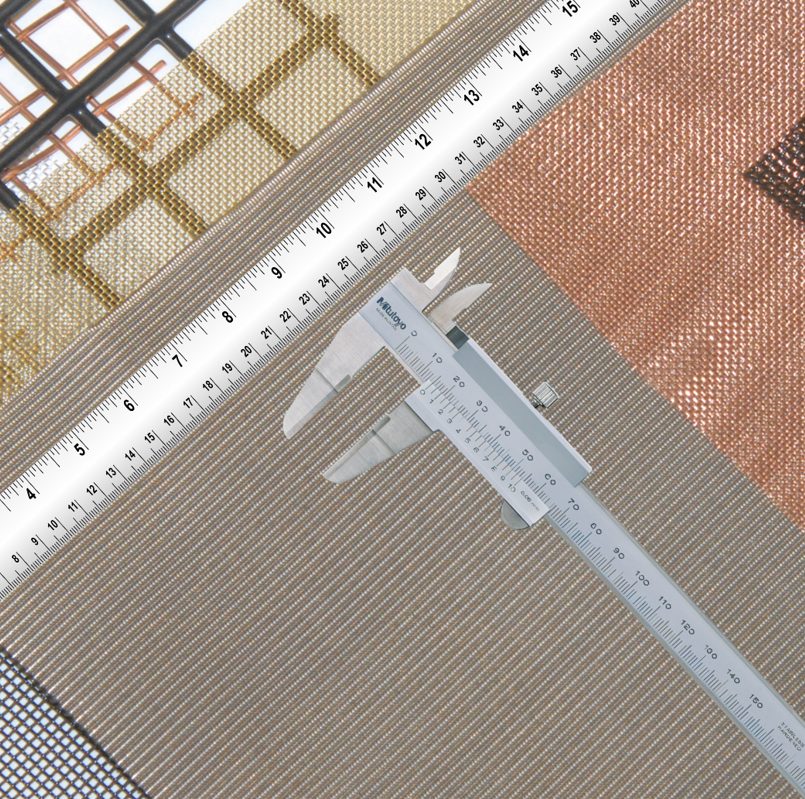

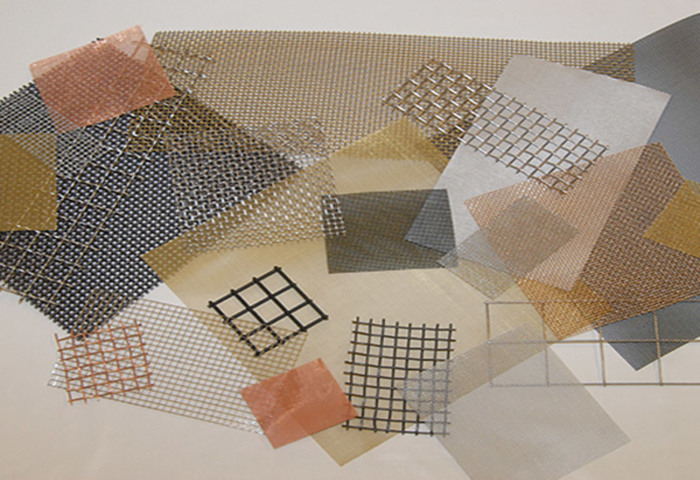

Read MoreBeginners Guide to Wire Mesh: Understanding How to Specify Wire Mesh or Wire Cloth for your Application

Woven and welded wire mesh come in endless sizes and variations. In this article, we will discuss how wire mesh is measured and the factors that go into determining the correct mesh size for different industries and applications. How is Wire Mesh Measured? Mesh Count Mesh count is one of the key parameters when specifying…

Read MoreFiber Molded Products: Shortening the Time to Market for New Products

Bringing any product to market is a lengthy and expensive process. In this article we will consider best practices for tooling prototyping and product development, giving special emphasis on prototyping deep-drawn products such as wire forms. Wire forms, here, refers to wire mesh, perforated, and expanded metals, all of which are Media Types used to…

Read MoreFiber Molded Products: Why Choosing the Correct Porous Media Is Essential to Efficient Production

Molded fiber production began over 100 years ago as a protective and efficient way to package more delicate goods such as eggs and light bulbs. Fiber molds can be formed to almost any shape and are able to absorb shock and avoid damage to the product. Now fiber molded products (sometimes known as pulp molded…

Read MoreThe Secrets Behind Slitting and Shearing

Cutting wire mesh or cloth to a correct specification can be challenging. Wire mesh does not behave like sheet metal and can easily fray or move out of line if the mesh is not set up properly. Cutting mesh or cloth is referred to as slitting, shearing, or both. Slitting wire mesh is cutting it…

Read MoreA Beginner’s Guide to Wire Mesh: The Basic Terminology

Each industry has its own specific terminology – and the wire cloth industry is no different. Below are the most common terms used when discussing wire, wire mesh and cloth, and the different types of weaves and manufacturing methods. Wire Cloth Terms Acoustic Mesh This mesh is woven to achieve specific sound attenuation objectives typically…

Read MoreA Beginner’s Guide to Wire Mesh: How to Choose the Correct Metal (or Alloy) for Wire Mesh Applications

Wire mesh, also known as wire cloth, is most commonly woven from stainless steel, however, with the right equipment and settings, almost all metal wire can be woven into a mesh. Below are the properties and features of different alloys and which applications suit them best. Metals and Alloys Aluminum Lightweight, good electrical conductor, and…

Read More