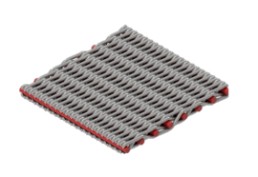

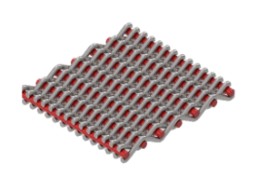

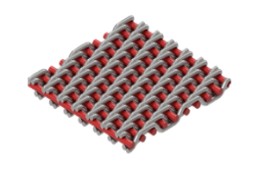

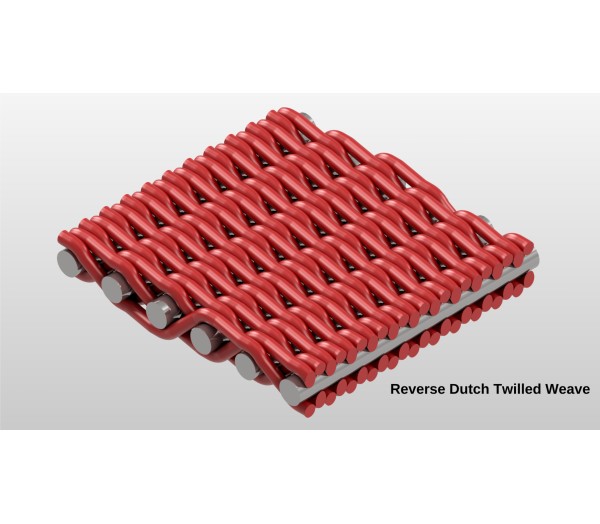

Reverse Dutch Twilled Weave

Reverse Dutch Twilled Weave An important version of the reverse dutch weave is the reverse dutch twilled weave. With this weave, the warp wires are also relatively thin – as in the case of the normal reverse dutch weave. The difference is the twilled weave pattern of the shute wires. This means that the warp wires are not as heavily deformed and physically stressed as in the case of plain weaves. The strength of this weave design is its suitability for applications that are subject to high levels of mechanical stress.

| Mesh Per Inch Warp x Shute | Wire Diameter, Warp in. (mm.) | Wire Diameter, Shute in. (mm.) | Porosity (%) | Thickness in. (mm.) | Weight, Stainless Steel lbs./sq. ft. (kg./sq. m) | Micron Retention |

| 72×15 | 0.018 (0.450) | 0.018 (0.450) | 58 | 0.069 (1.75) | 0.91 (4.43) | 400 microns |

| 132×16 | 0.014 (0.022) | 0.022 (0.560) | 45 | 0.049 (1.25) | 1.11 (5.40) | 350 microns |

| 132×16 | 0.014 (0.352) | 0.018 (0.457) | 58 | 0.049 (1.24) | 1.00 (4.90) | 250 microns |

| 132×18 | 0.014 (0.355) | 0.018 (0.455) | 57 | 0.052 (1.31) | 0.95 (4.65) | 200 microns |

| 152×24 | 0.012 (0.315) | 0.014 (0.355) | 42 | 0.047 (1.20) | 0.93 (4.53) | 165 microns |

| 160×16.5 | 0.012 (0.305) | 0.014 (0.355) | 44 | 0.041 (1.04) | 0.87 (4.26) | 125 microns |

| 160×24 | 0.012 (0.305) | 0.016 (0.400) | 42 | 0.043 (1.09) | 0.96 (4.68) | 150 microns |

| 160×25 | 0.012 (0.315) | 0.016 (0.400) | 39 | 0.043 (1.10) | 1.02 (4.97) | 145 microns |

| 228×36 | 0.007 (0.190) | 0.011 (0.280) | 47 | 0.026 (0.67) | 0.56 (2.71) | 100 microns |

| 260×40 | 0.006 (0.150) | 0.009 (0.220) | 53 | 0.024 (0.62) | 0.41 (1.98) | 125 microns |

| 325×39 | 0.006 (0.150) | 0.012 (0.300) | 43 | 0.028 (0.70) | 0.56 (2.71) | 55 microns |

| 400×120 | 0.003 (0.065) | 0.004 (0.100) | 61 | 0.010 (0.26) | 0.15 (0.72) | 60 microns |

Alternative Micronic Weaves