Our Capabilities

With over 60 years in business as North America's largest supplier of wire mesh, we've learned a thing or two about producing quality wire forms. We can work with you on design, prototyping, and manufacturing - lowering the costs and time of new designs to market, delivering a high-quality wire-formed product to you so you can concentrate on meeting your customers' molded pulp container deliveries.

Individualized Inventory Control

Do you incur high Forming $$ costs from producing your wire forms?

- High scrap costs?

- Multiple rework costs?

- Resource Intensive?

Let us help you lower your cost of wire form production!

We can help you lower your production costs by working in the following areas:

- Provide a full Engineering service for your tooling

Our engineers will work with you to design and manufacture your tooling and complete the prototype process. - Recommend the media required to make your wire form

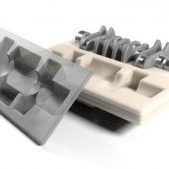

We'll examine the requirements for your product and determine what your wire form should be made from (wire cloth, perforated or expanded metal) for optimal quality and the lowest cost of ownership. - Manufacture your pulp/fiber molded wire forms

We'll use our expertise to manufacture your wire form to your exact specification using our in-house annealing and production stamping capabilities, producing great quality, cost-effective wire forms. - Provide Inventory Control Programs

We'll keep your production line stocked with our personalized Continuous Replenishment System (CRS).