Technical Bulletins

Understanding Micron Mesh Filters, Part Four: Case study – What not to do when designing with filtration wire mesh

A filtration system manufacturer was creating a filter assembly to meet a seawater regulatory specification with a 25-micron rating. They…

3 Benefits of Wire Mesh for Electrolyzers & Fuel Cells

The demand for new renewable energy sources is giving rise to new-generation fuel cell development and hydrogen production using electrolyzers….

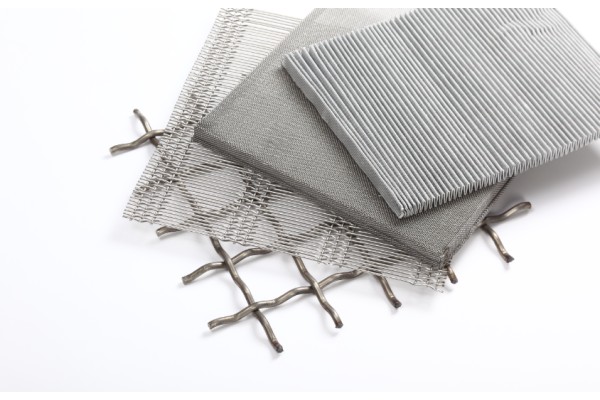

Understanding Wire Mesh Retention Ratings: Nominal vs. Absolute Micron Retention

Wire mesh is a versatile material consisting of parallel rows and intersecting columns of wire. It comes in many different…

How does the Cold Bond™ Manufacturing Process enhance Wire Mesh?

Cold Bond™ is a unique metallic bonding process developed to stabilize wire mesh for batteries, fuel cells, green hydrogen production…

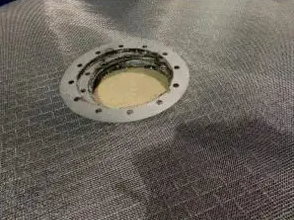

Micron Mesh Filters – Part Three: Manufacturing Filtration Wire Mesh Components for Lowest Cost of Operation

In part three we separate the possible from the practical and discuss manufacturability or forming of the wire mesh media…

Micron Mesh Filters – Part Two: Balancing the Durability and Aperture of Filter Mesh

For this series on understanding wire mesh for filtration, in part one we discussed different mesh weaves and their roles…

Micron Mesh Filters – Part One: Evaluating 6 meshes each with a 60 micron retention.

Selecting a micron wire mesh can be a daunting task. To better understand the complexities of mesh selection overall, let’s…

Separator Machines Working Principles: Lead Angle, Material Flow Path – How they affect your Productivity Throughput

What is the Lead Angle? The lead angle adjustment controls the path the material travels across the screen. In round…

Choose the Right Deblinding Screen for your Application

Using a vibratory separator machine is a reliable method of sorting, classifying, and cleaning a wide range of materials, both…

How to Keep Screen Replacement Cost Low

With the price of raw material skyrocketing, many manufacturers using Vibratory Separator Machines are wondering – how do we keep…

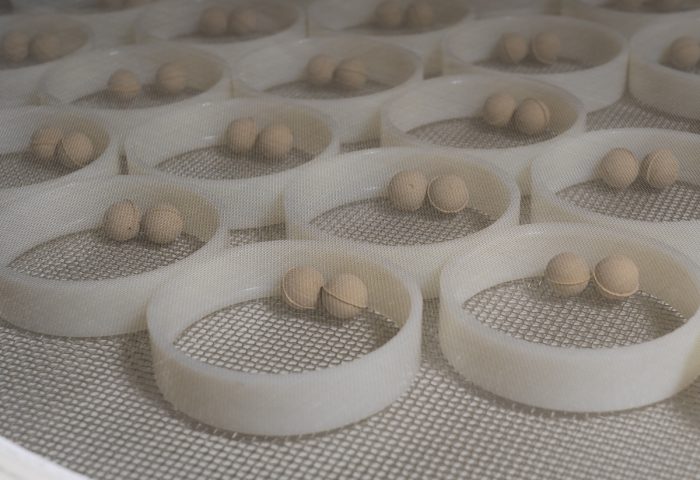

Case Study: How one Fiber Molding Manufacturer significantly lowered their cost of production

Production of Fiber molds (sometimes called Pulp molds) used for food and other containers has increased significantly in the last…

Fiber Molded Products: 6 Ways To Minimize Scrap

#1: Select Best Porous Media Type #2: Determine Correct Heat Treatment #3: Optimize Blank Layout Choosing the best porous media…