Micron Mesh Filters – Part One: Evaluating 6 meshes each with a 60 micron retention.

Selecting a micron wire mesh can be a daunting task. To better understand the complexities of mesh selection overall, let’s consider the more limited example of just choosing a 60-micron filtration mesh. We will first discuss some of the variables in what you expect the mesh to accomplish, followed by a comparison of the ways of weaving different characteristics into the mesh, then conclude with ways an experienced mesh partner can avoid costly and wasteful pitfalls.

When you call a micron filter mesh supplier and tell them you would like a 60-micron mesh, to recommend the right one they will have several questions. Some you may have anticipated and others you probably did not.

- How much differential pressure will the mesh be subjected to?

- What is the desired volumetric flow rate through the mesh?

- How will the mesh be mounted? Will it need a support structure?

- Will it need to be pleated, punched, or formed?

- Will the edges be welded, crimped, glued, hemmed, or over-molded with plastic?

- How will all this be implemented for manufacturability, accounting for material cost and availability?

After considering your answers to these questions, your mesh expert will consider a variety of nominally 60-micron mesh weaves and a few close matches. They’ll think about which one’s unique characteristics would make it the most suitable one for your application.

Wire Mesh Weaves and Specifications

| Weave | Mesh count | Micron | Warp Wire Diameter (mm) | Shute Wire Diameter (mm) | Open Area | |

| 1 | Standard Sieve Size | 230 | 65 | |||

| 2 | Tensile Bolting Cloth | 300 | 56 | 0.03 | 42% | |

| 3 | Mill Grade | Not Available | ||||

| 4 | Market Grade | 250 | 61 | 0.04 | 36% | |

| 5 | Dutch Weave | 50*250 | 55 | 0.006 | 0.004 | 61% |

| 6 | Dutch Weave (Double Warp) | 28*160 | 60 | 0.25 | 0.18 | 44% |

| 7 | Dutch Twill | 40*550 | 65 | 0.180 | 0.10 | 52% |

| 8 | Reverse Dutch Twill | 400*120 | 60 | 0.065 | 0.1 | 61% |

| 9 | Reverse Dutch Plain | 175*50 | 60 | 0.15 | 0.3 | 53% |

| Natural silk thread | 0.007 | |||||

| Human hair | 0.07 |

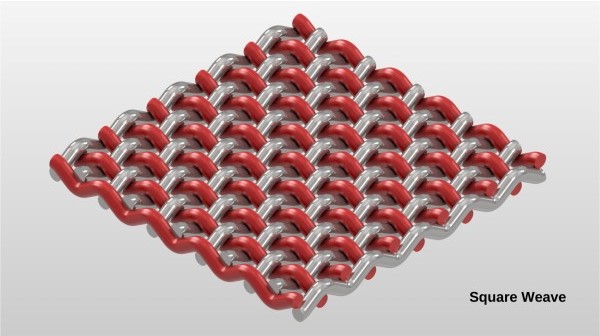

Square Weave Mesh

The first four on the list are what most people think a micronic woven filter is: a square weave, like the familiar bug screen, only finer. In fact, square meshes that fine tend to be too fragile for most filtration applications. Research shows that prior to reaching out to a mesh expert, only about 1-in-5 customers know that different mesh weaves other than square-weave exist.

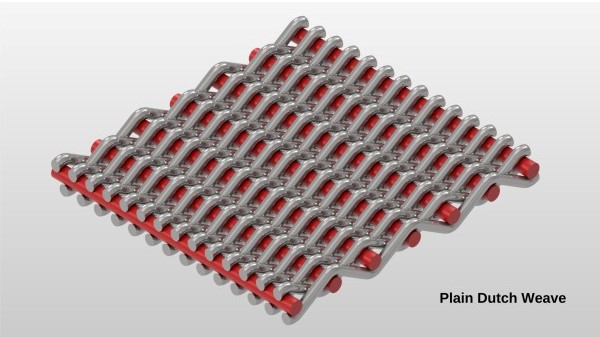

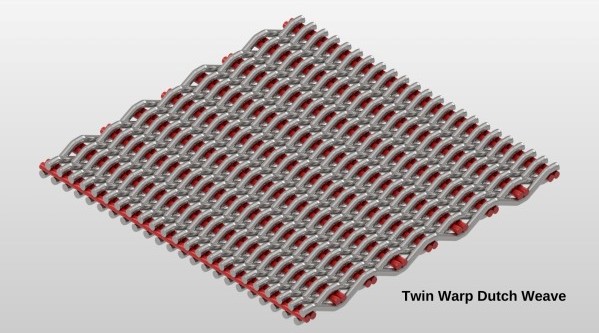

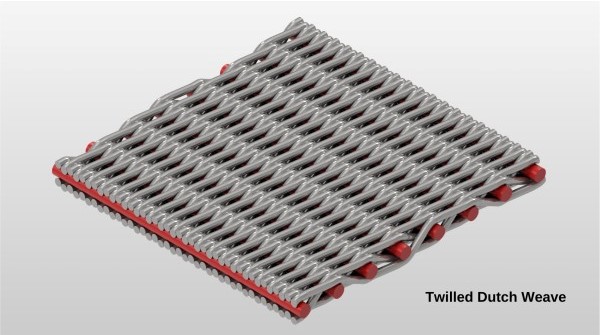

Dutch Weave Mesh

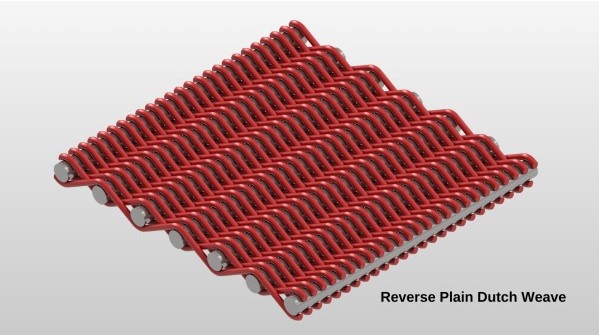

A variety of Dutch-weave meshes were developed to be more durable than square weaves for filtration. A Dutch weave is one in which the warp wire is larger than the shute wire, and a reverse Dutch weave is one in which the warp wire is smaller than the shute wire. With these weaves, the larger, more widely spaced wires add strength while tightly spaced smaller wires maintain the micron retention. The complexity of these weaves means that predicting how easily fluid passes through the mesh is more complicated than just measuring the open spaces between wires. Instead, flow resistance must be determined either by:

- comparing flow rates of a sample compared to a calibrated standard, then calculating the pressure-drop coefficient for that mesh – or

- by real-world measurement of the pressures on either side of the mesh in situ.

Wire Mesh Weave Comparison

| Weaves 1-4: Meshes 1-4 are all square weave meshes, meaning the warp and shute are of the same thickness and spacing in both directions. Of those that are available at a 60 micron retention, none of them are much stronger than tracing paper. |

| Weave 5: Plain Dutch Weave. In plain Dutch weave the warp wires (in red) are thicker than the shute wires (in silver). Thicker wires make it easier to weld, but stiffer and harder to form or pleat. Holds up well under high pressures. |

| Weave 6: Double warp Dutch weave. Thinner wires than plain Dutch make it harder to resistance weld, but manageable with laser welding. Greater flow rate than plain Dutch with low pressure differential. Note the twin warp wires (in red). |

| Weave 7: Dutch Twill combines the features of a Dutch weave and a twill weave. It has thicker warp wires (in red) than shute wires (in silver). While it practically qualifies as a 60 +/- micron mesh, this weave is too fine to be used for filtration applications as it is unable to withstand the pressure differentials. |

| Weave 8: Reverse Dutch Twill. For this weave the warp wires are thinner (in red) than the shute wires (in silver) Smallest wire diameter. Easy to work with. Does not hold up to pressure well. Excellent particle retention versus regular Dutch weaves; however, not a commonly stocked item. Usually only available as custom order with long lead times. Most costly as utilizes most metal wire. |

| Weave 9: Reverse Dutch Plain. In this weave the warp wires (in red) are much thinner than the heavy shute wires (in silver). Thicker, stronger than plain Dutch. Good for long narrow profiles that coil lengthwise easily but resist bending over the width. Withstands very high differential pressure. |

Once a mesh’s micron retention and anticipated particle accumulation rate have been considered, the next step is to determine how much surface area of mesh is needed to meet the overall filtration requirements.

Consider the Shape of your Filter and Filter Mesh

If the necessary surface area is less than space allotted for the filter, rolling, pressing, or pleating the mesh into a shape is necessary to increase the surface area for the filtrate to pass through. This means the manufacturability of the weave chosen needs to be considered. Once formed, how will it be held in place? Will the filter need frequent cleaning? Will it be cleaned by back flow, or by removing the filter from its housing? Will it need to be welded to a support structure to facilitate that cleaning or to make removal practical?

Some of the more robust Dutch weave meshes are too stiff for a pleating machine, whereas others are too thin for a welding machine. One mesh might have a 1% improvement in flow rate but a 500% increase in cost.

When it comes to selecting a woven wire filtration mesh, each of these factors and more are why early collaboration with a mesh filtration application engineer is an opportunity to sort the practical from the possible.

Partner with a Mesh Expert

Talking to a mesh expert about your 60-micron filtration needs, or any other inquiry you may have about wire mesh, will not just help you to avoid common costly pitfalls; it will get you the mesh that is optimal for the job instead of merely sufficient.

Gerard Daniel’s Expertise

At Gerard Daniel, we’ve been sourcing, weaving, and distributing wire mesh for 70 years and stock the largest range of inventory in North America. Our application engineers use their deep expertise in woven mesh and components to develop the most effective solution, collaborating with your design, development, and production teams to ensure the lowest cost to manufacture.

Please reach out if you would like to learn more about our capabilities.