Fiber Molded Products: Minimizing Scrap and Lost Production Time when Drawing Wire Forms

In the metal fabrication industry, drawing has two meanings. One is the drawing of wire by taking it through a die to reduce its diameter. The second type of drawing is the process of forming metal, such as wire mesh or sheet metal, over a tool to create a three-dimensional shape. Through heat treating, the temper of the metal can be altered to allow an even wider range of design considerations. In this article, we consider the merits of the second type of drawing and apply these to wire forms as part of our series to support the production of fiber molded products (sometimes called pulp molded products). Wire form refers to wire mesh, perforated and expanded metals, all of which are used to produce wire forms.

Drawing Wire Form Advantages

There are various techniques that can be used to fabricate wire forms, however, deep drawing wire forms have many

advantages that make it a top choice for fiber mold applications:

Efficiency & Speed

Once design and tooling are approved, using a repeatable drawing or forming process allows for efficient mass production of deep drawn forms.

No Assembly Required

In the drawing, one blank is cut to size and drawn into a 3D shape. Typically, no additional assembly of various components is needed, however, in some deep-drawn or multi-pocket articles, multiple wire forms may be necessary.

Little-To-No Waste

Forms are created from blanks with specific dimensions that are pre-determined so that there is the smallest amount of scrap left over when the final product is complete. Skeletal scrap and any remaining product can then be recycled at the manufacturing facility.

Endless Repeatable Shaping Possibilities

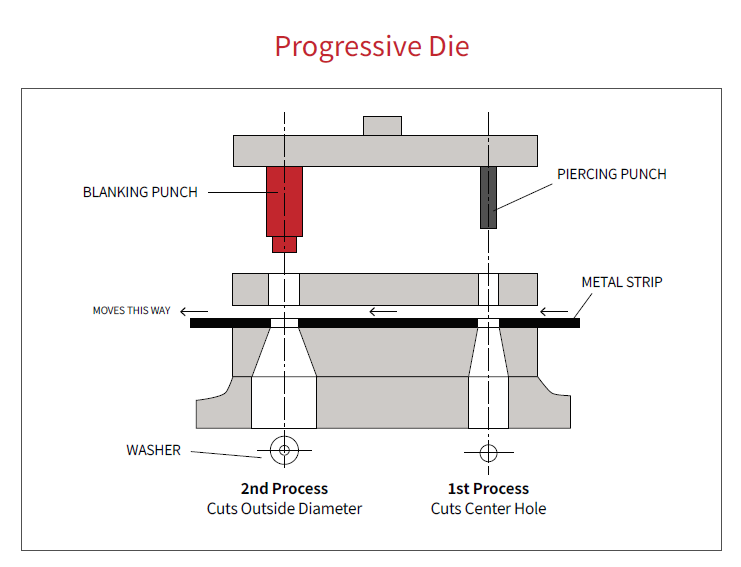

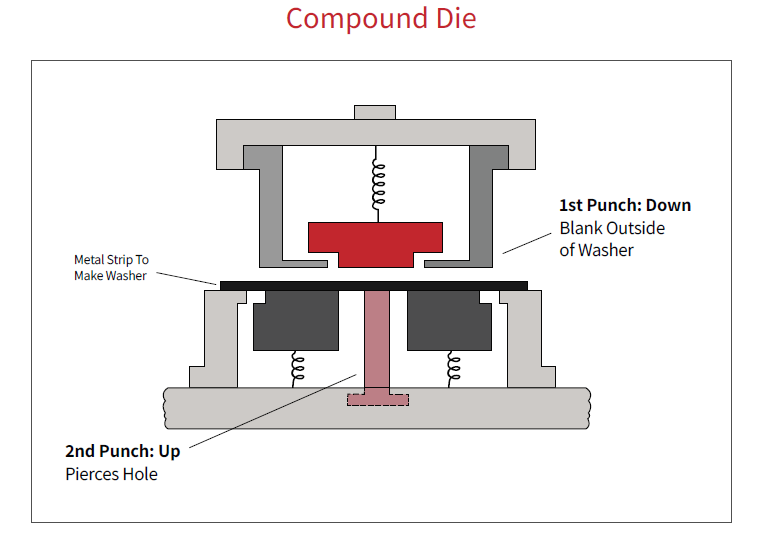

The creation of a wide range of geometric shapes is possible through the correct combination of media and temper. One thing to consider during design is that the opening at the top of the part must be wider than the bottom. The use of progressive or compound dies allows the metal to form more intricate shapes in a multi-stage punch process, trimming and forming the edges of a piece in the same operation. See images below – Two-stage forming using Compound or Progressive Dies.

Producing Drawn Wire Forms

Producing deep-drawn wire forms requires a knowledge of the many different areas that can influence production and quality rates. Each of these areas must be optimized to ensure repeatable production and minimal scrap rates:

Correct Metal Media Type

There are many combinations of alloy, media form, and other parameters. Each will have an effect on the production of the wire form and should be considered with the customer’s requirements. Learn more about selecting the correct media for your project here.

Development of Prototype

A solid prototype tooling process will allow the correct form to be developed meeting the customer’s requirements (which may not have been completely defined). This allows optimum collaboration to finalize the design and get the wire form to the fiber mold manufacturer quicker. Learn more about how to optimize the prototyping process for wire forming here.

Correct Heat Treatment

Annealing can be an essential step in the preparation of the media to increase the malleability as it enters the drawing process. Proper annealing practices will eliminate work hardening created during the weaving operation. During the drawing process, depending on the type of media, depth of the form, and tightness of the radii, the form may need to go through multiple heat-treating processes.

Production of Wire Mesh Forms

The prototype process will have optimized many of the variables that can cause quality defects. Below, in the following table, is a summary of the main types of defects that can occur in production.

Quality Control

The first articles created on the production tooling line should be verified by the quality department for dimensional layout and adherence to part specifications. During production, all parts should be visually checked and periodically dimensionally checked.

| Quality Defect | Production Cause |

| Wire form cracks or splits | Metal media incorrectly heat treated |

| Rips or wrinkles in the form | Press is operating too fast, improper heat treatment or not enough lubricant in the press |

| Form is not rigid | Metal media is not correct for the strength required |

| Fiber / Pulp mold has an unacceptable surface finish | Metal media used has too large of an opening, causing a ‘ripple’ effect on the pulp mold when the liquid is extracted |

| Overlaps in the form | Incorrect lubrication used or blank size too large |

| Wire forms have a very short production life | Incorrect metal media may have been chosen or material may have become embrittled during forming |

Effects on the Bottom Line

If the wire forming process is not optimized, unacceptable scrap levels can occur. This in turn will affect the bottom line of the pulp mold manufacturer using the wire forms. While many do have the capacity to produce their own wire forms, there is the potential for this process to turn into an uncontrolled cost center if not carefully managed. One way to do this is working in partnership with a company specializing in deep draw forming. This helps manufacturers reduce cost, save time, re-allocate manpower, and ultimately focus on the production of pulp molds for their customers.

Gerard Daniel Worldwide is a leader in wire cloth, associated wire mesh components, and deep-drawn products. We are skilled at managing the whole deep drawing wire form process from media selection, tooling prototyping, design finalization, and production of wire mesh forms. We also have a well-established just-in-time customer delivery program and supply many sectors, including the packaging, food, and beverage industries.