How to Keep Screen Replacement Cost Low

With the price of raw material skyrocketing, many manufacturers using Vibratory Separator Machines are wondering – how do we keep our costs of replacement screens at a manageable rate?

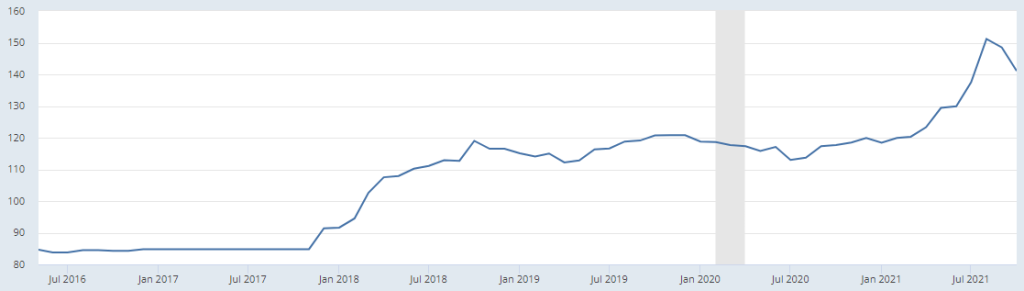

According to the office of the U.S. Bureau of Labor Statistics, the stainless-steel index has increased more than 29.5% over the last year, realizing an approximate 80.4% increase over the last five years, comparatively trending along with many other raw material costs.

Some Vibratory Separator manufacturers save their customers money by running an in-house re-screening program for pre-tension screens. Initially started to meet their customers’ sustainability goals, many did not realize how such a program would pay off financially, especially in the current economic climate.

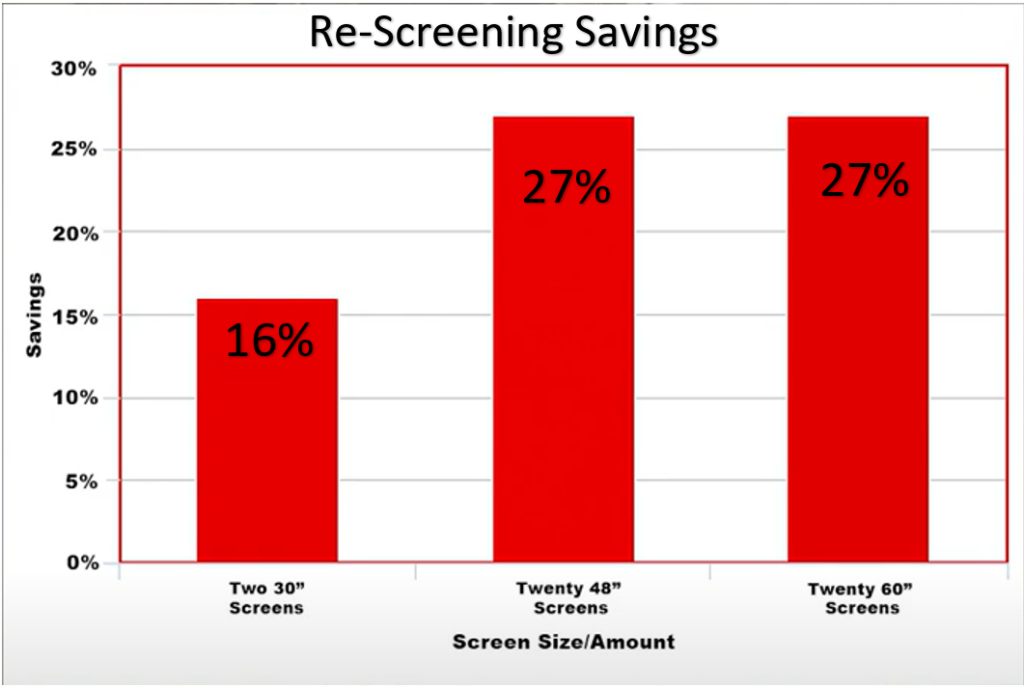

A program generally works as such; the customer stores their ripped, clogged, or blinded screens until they have more than 20 (fewer can be returned, however, 20 is the magic number where savings really start to show). Some manufacturers arrange pick-up directly from their customers and incorporate the freight into the new screen price.

When the sieve screens first arrive back at the original manufacturer, they are inspected carefully for rim damage. Assuming no rim damage is found, the mesh is then removed from the rim. This can be done in a number of ways, but great care must be taken that the rim is not damaged during this process; otherwise performance will be affected, and the rim cannot be used.

Then, the new mesh is applied to the rim; cured, inspected, and then shipped back to the customer. Below is a graph showing the average savings a customer could save. The savings are more dependent on the number of screens returned rather than the location of the customer.

Additionally, re-screening also gives a customer the opportunity to switch out the mesh; whether it is not providing optimum performance, or to enable the manufacturer to pivot into a different applicational need. In the case of performance, perhaps the mesh needs to be changed from a Mill Grade spec to a Tensile Bolting Cloth spec for improved productivity. Or simply, for increased flexibility, the customer wants to use the screen for a different application and therefore needs a different mesh count, while saving cost. A good manufacturer will be able to provide an application engineer to work with the customer and determine what they need.

Gerard Daniel has been operating a successful re-screening program for over 2 years. Ron Hoke, the operations manager, proudly states; “Our customers are delighted when they realize they can save up to 25% on their new screens. Our proprietary cleaning and preparatory line ensure that the screens operate as new when they are delivered to the customer.” For more information about re-screening your used and damaged screens, contact us today.